Description

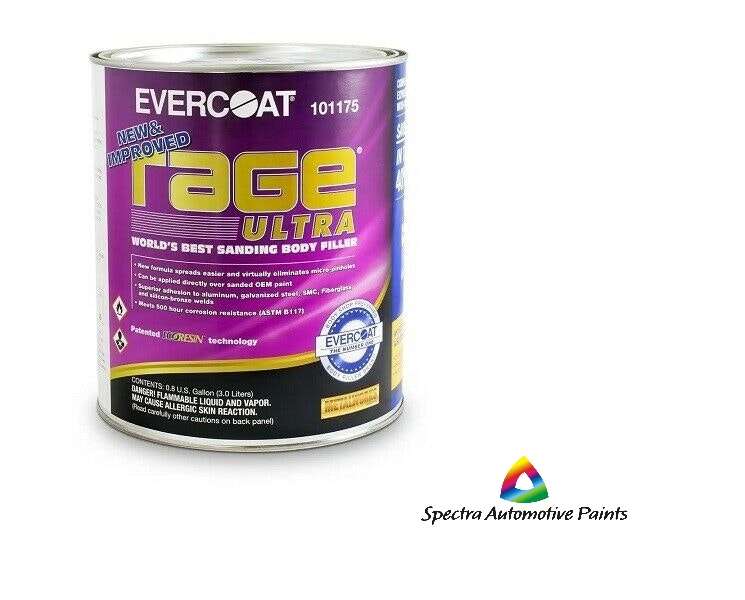

Evercoat Rage Gold Ultra 3Lt with Hardener

Rage® Ultra is the world’s best sanding body filler. Its unparalleled sanding qualities are a result of the patented EcoResin™. Its non-sag formula has excellent filling properties, while eliminating the need for finishing putty. Rage® Ultra is part of the Metalworks® system.

- New formula spreads easier and virtually eliminates micro-pinholes.

- Can be applied directly over sanded OEM Paint.

- Superior adhesion to aluminum, galvanized steel, SMC, Fiberglass and silicon-bronze welds.

- Meets 500 hour corrosion resistance (ASTM B117)

- Save up to 36% in time & up to 40% in material on dent repairs.

RAGE ULTRA is the new light-weight, universal, premium filler for 90% of the everyday repair processes. Through the unprecedented curing and sanding features the repair process is not only significantly speeded up but also markedly increased in quality. Save time, material and eliminate costly re-work!

RAGE ULTRA does not feel or look like a normal filler. There is a good reason for this; The low viscosity of the material encourages the correct application of layers of material. This results in an even, smooth, pin-hole free surface. The patented formula, containing the new premium , allows itself to be sanded during the curing process. In this case the initial sanding process can be started at 8-10 mins. In addition to the fast curing, RAGE ULTRA also possesses exceptional light sanding characteristics. An unprecedented amount of stock removal can be achieved without effort or changing of abrasive.

- The very latest filler technology

- Unique, sustainable premium giving unprecedented curing and sanding benefits

- Reduces application and sanding time by up to 46%*

- Improved sandability by up to 30% reduced abrasive consumption

- Even, pin hole free application of material

- Exceptional adhesion with a super smooth finish

SUBSTRATES

Exceptional adhesion to a variety of suitably abraded substrates including: OE paint &

clearcoat, steel, galvanised steel, zinc coated steel, aluminium, composite plastics, hard plastics, SMC, polyester filler.

PREPARATION

Before sanding, thoroughly clean the area to be repaired removing all traces of dirt, oil and wax residues

Lightly abrade the repair area to key the surface P80-P180. Use a fine abrasive to remove any deep or heavy scratch pattern P180-P220. Remove the dust. The area to be repaired must be completely dry before application of product.

Lightly abrade the repair area to key the surface P80-P180. Use a fine abrasive to remove any deep or heavy scratch pattern P180-P220. Remove the dust. The area to be repaired must be completely dry before application of product.

MIXING

The mixing ratio is 2% by weight. Place the required amount of hardener on a clean, grease free, mixing board and add the requisite 2% hardener. Refer to the illustration on the product lid for an optical guide to ensuring the correct ratio. Thoroughly mix the material to a consistent, homogeneous mass that is one uniform colour. Only use the EVERCOAT hardener provided.

APPLICATION

First, apply a very thin layer of mixed material with firm pressure to the repair area. This promotes an optimum, pin-hole free application and excellent adhesion. Increase to the desired depth of repair by applying layers of product.

FINISHING

The sanding process can usually begin after appx 8-10 mins. The initial sanding can be started with P80 – P220 grit.

TECHNICAL DATA

Colour Light grey

Physical State Liquid

Solubility Not soluble in cold and warm water

Working time 3-5 minutes

Dry to sand time 15-20 minutes

Corrosion Protection 500 hours salt spray (Harshaw)

Maximum build 6 mm (sanded)

VOC EU limit for volatile organic compounds: 250 g/l (2007)

This product contains max 51 g/l VOC

Physical State Liquid

Solubility Not soluble in cold and warm water

Working time 3-5 minutes

Dry to sand time 15-20 minutes

Corrosion Protection 500 hours salt spray (Harshaw)

Maximum build 6 mm (sanded)

VOC EU limit for volatile organic compounds: 250 g/l (2007)

This product contains max 51 g/l VOC

The properties are typical values and not to be considered as technical sales specifications.

The physical test was at about 25 °C and 75 % relative humidity unless otherwise specified.

Reviews

There are no reviews yet.